Procurement Digitization in Post-Pandemic Era

The Case for Digital Procurement is Stronger than Ever

In just a few months’ time, the COVID-19 crisis brought about years of change in the way companies in all sectors and regions do business. Almost all companies have accelerated the digitization of their customer and supply-chain interactions and of their internal operations. Nearly all companies stood up at least temporary solutions to meet the new demands on them, and much more quickly than they had thought possible before the crisis. Now companies expect these changes to be long lasting and are already making the kinds of investments that ensure they will stick.

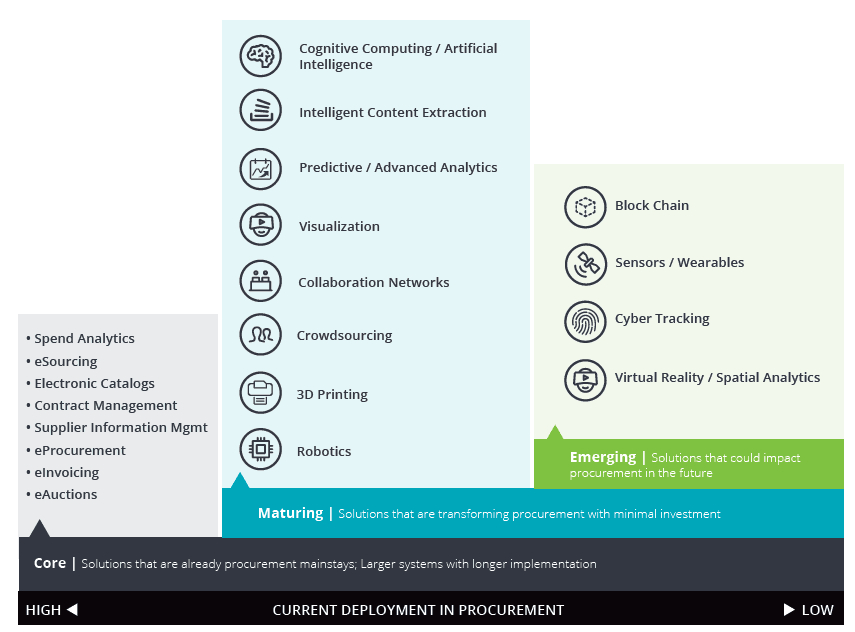

Digital Technologies and Capabilities

Procurement technologies are advancing rapidly, moving through a regular cycle from emerging, to maturing, until widely adopted as core (Figure 1). Most organizations deploy several forms of core procurement technologies. These platforms usually include a combination of spend analytics, eSourcing, contract management, and eProcurement (eCatalogs, eInvoicing), among others. These core systems have typically been characterized by deployments requiring healthy amounts of capital spending and significant systems integration work.

In contrast, today’s maturing and emerging solutions tend to be much quicker to deploy. Many use Software as a Service (SaaS) models, do not need significant preparation of data or systems, require no or light integration, and can produce results within days or weeks. The following digital solutions and capabilities have entered the maturing phase and will soon be core procurement digital functionalities:

Cognitive computing and artificial intelligence:

Leverages pattern recognition software and iterative machine learning algorithms to rapidly categorize unstructured spend, cost, contract, and supplier data. For example, information like raw Accounts Payable (AP) records or Travel and Expense (T&E) systems extracts not within the traditional structure of an Enterprise Resource Planning (ERP) system can be utilized to deliver new insights and opportunities.

Intelligent content extraction:

Many times based on Optical Character Recognition (OCR), this uses learning algorithms to read unstructured documents such as PDFs of contracts, specification drawings, and Bills of Materials (BoMs), and rapidly extract critical pieces of data like pricing tables, payment terms, and termination clauses that would have taken days or weeks to assemble.

Predictive and advanced analytics:

Combines modeling, statistics, machine learning, and artificial intelligence with multiple third-party data sources to predict the most likely scenarios for cost/price fluctuations, demand, supplier/country risks, etc. and enable proactive decision making.

Visualization:

Transforms data into user-friendly, executive-friendly, visual formats (such as dashboards) that can simplify decision making by organizing information and delivering fresh insights and recommendations.

Collaboration networks:

Platforms that provide buyers and suppliers with visibility into all elements of their joint value chains. Users can maintain supplier information in the cloud; measure, analyze, and manage supplier performance; uncover joint process improvement opportunities; and identify, monitor, and escalate supplier risks.

Crowdsourcing:

Through the capture of large and diverse inputs (e.g., data, sentiment) and usually leveraging mobile technology, organizations can monitor trends and events impacting supply chains and supplier performance.

3D printing:

Additive manufacturing, or 3D printing technology, can quickly make a physical object from a digital model by laying down (i.e., adding) layers of a material. This is done via processes such as extrusion of thermoplastics, ultraviolet curing of resin, or laser sintering of metallic powders, among other methods. Currently used mostly for rapid prototyping of goods, the technology has the potential to eventually eliminate some kinds of stocking activities for low-volume items, replacing them with on-demand production. Rapid prototyping will become an integral part of the strategic sourcing process for direct materials.

Robotics:

As it relates to procurement, Robotics Process Automation (RPA) is software that recognizes and learns patterns and can perform rule-based tasks. This process automates multiple repetitive manual tasks such as some Procure-to-Pay (P2P) tasks, driving efficiency and reducing errors and risks in execution. Four emerging solutions will affect procurement in the future, and procurement leaders should be educating themselves and preparing for adoption:

Blockchain:

This cryptologic data structure uses a trusted peer-to-peer network to create digital transaction ledgers which can verify and validate transactions in the P2P process (or any other supply chain process) and then trigger automated payment.

Sensors and wearables:

Devices that detect, capture, and record physical data. These devices can note the movement of goods and inventory levels and enable audit tracking during site visits.

Cyber tracking:

Real-time tracking of online or physical activity enables proactive monitoring of supplier behavior and performance. When combined with third-party data, the technology can deliver trends and predictions on supplier (or supply chain) risks.

Virtual reality and spatial analytics:

Detecting events or changes of status using video, location data, or pattern analysis, and conducting supplier visits or audits can empower procurement professionals to do more with less. As a stand-alone deployment, each of the solutions mentioned above brings additional value to procurement. However, organizations that combine multiple technologies and solutions could see the value of their deployments grow exponentially.

Given the pace of change, procurement leaders should consider the relevance of these disruptive technologies within their own organizations and if applicable, take every opportunity to expose their organizations to them.

Today’s digital technologies, and the degree to which the capabilities are being deployed in procurement

Procurement Digitization a paradigm shift

Digital transformation is affecting most areas of business. As a result of this digitization process, the procurement mandate has radically shifted from having a purely ‘transactional’ focus to a ‘strategic’ focus. The expectation has shifted from tactical Key Result Areas (KRAs, e.g. achieving cost-effective purchases with the help of low-risk suppliers) to highly strategic ones such as providing high added value through high-spend visibility, real-time analytics and intelligence, eliminating unnecessary tail-end spend, and aiming to improve savings targets while reducing cost-to-serve.

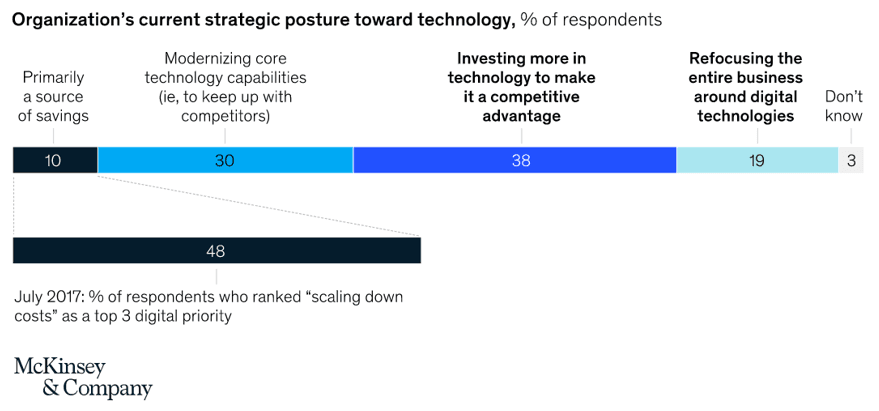

According to a recent survey, the pandemic has brought not only the multiyear acceleration of digital, but the crisis has brought about a sea change in executive mindsets on the role of technology in business. In the McKinsey Global Survey of executives 2017 survey, nearly half of executives ranked cost savings as one of the most important priorities for their digital strategies. Now, only 10 percent view technology in the same way; in fact, more than half say they are investing in technology for competitive advantage or refocusing their entire business around digital technologies.

Executive mindsets on technology’s strategic importance have changed radically during the crisis

Today, purchasing is a business function with many external and internal interfaces. These include partners and a wide range of suppliers around the world, regulators and internal compliance, R&D, finance, production, logistics, and, of course, customer management – all of whom are connected to procurement via physical and digital transaction and communication. The complexity and diversity of this environment, the substantial number of transactions and the large amount of data make purchasing a central player in the corporate transformation. Now, procurement teams have the opportunity to position themselves within the organization as a provider of business insight and business foresight – thus having a significant impact on the overall performance of the company. However, better and more precise decisions, strong operational excellence, quality, compliance, and cost reduction are only fully possible by following a holistic approach. This means focusing on the entire process landscape of purchasing, leveraging the full spectrum of Information Technology (IT) tools, and executing a mind shift in the procurement organization.

Building the roadmap for Procurement Digital Transformation

In the remote work era, it is imperative to have business applications that an employee can use from anywhere and at any time. Procurement is no exception. When operational challenges arise, many organizations do not have the right tools and technologies to help manage their financial and procurement functions away from their office desks. The use of physical papers, whether it be mail, invoices, or even cashing checks, creates avoidable inefficiencies and costly errors. Companies can no longer afford a slowdown related to purchasing and AP functions.

Digitizing and automating the Procure-to-Pay process can greatly benefit organizations, even once they resume business as usual. Digital procurement allows you to track numerous assets, such as spend, purchase orders (POs), invoices, goods, supplier data and more, all in one convenient and easy-to-use platform, ensuring spend visibility and transparency. Armed with a holistic view of operations and properly managed spend, procurement leaders can make smart, informed financial decisions both immediately and into the future.

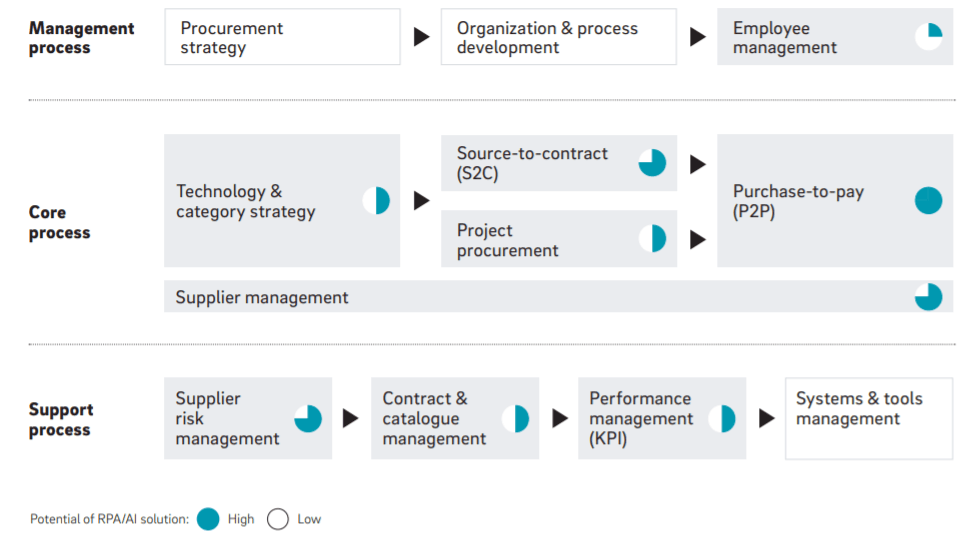

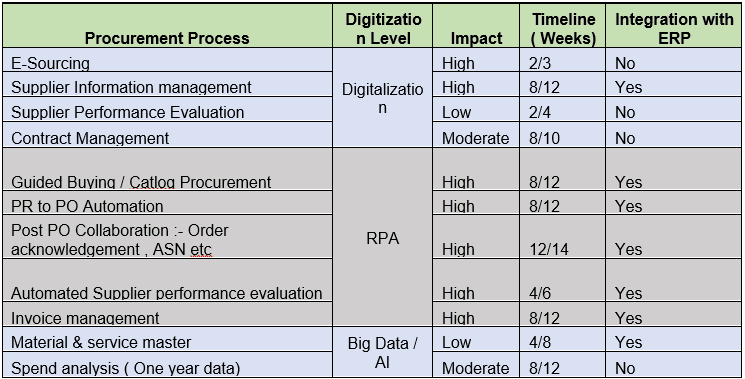

We need to analyze the impact of procurement digitization initiatives on overall procurement processes and take a decision on the digitization journey.

The impact of RPA /AI varies across the procurement value chain

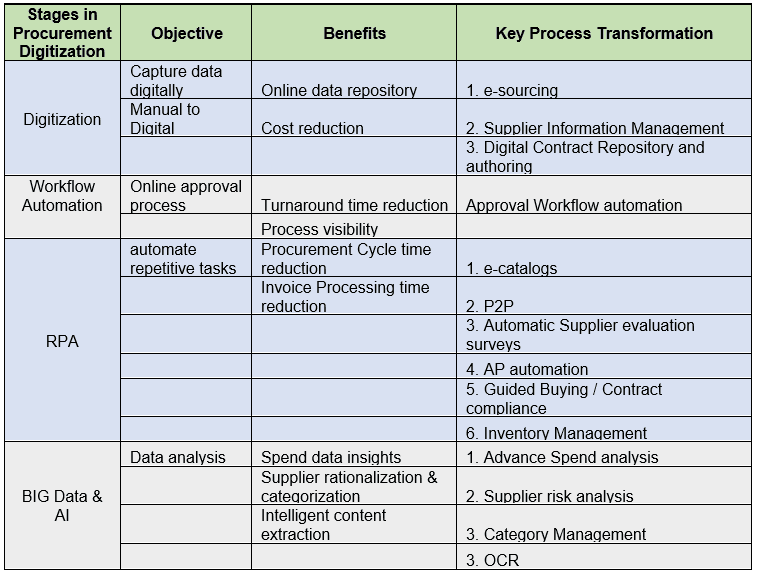

Stages in Procurement Digitization

The value-adding use of AI in purchasing requires a solid technological foundation, which must first be built. Following is the multi-stage process to create maturity in the procurement organization,

a. Digitization

It is possible to mitigate typical problems, such as fragmented IT systems, data silos, or inadequate quality with modern tools and systems. Initially, this means making the right data accessible across the entire procurement organization. As a first step, organizations need to target all manual procurement processes such as sourcing, supplier information management, contracts repository, etc. Management of these processes is generally outside the ERP system and hence it is difficult to get visibility and data around the same. Implementation of Online Supplier Relationship Management (SRM), e- sourcing & e-contracts will help us digitize the processes.

b. Workflow Automation

In the next step, the focus will be on the basics of workflow automation, whereby a combination of (cloud-based) ERP systems and ultramodern SRM suites usually makes sense.

c. RPA (Robotic Process automations)

On top of these standard applications, robotic process automation can quickly automate repetitive tasks without a lot of programming effort.

d. Big Data & AI

Once these foundations are in place, a platform exists on which truly cognitive artificial solutions can be built. In particular, the interaction of big data and AI can provide support for complex, strategic issues. Even without the use of AI, the analysis of large amounts of data can add value – be it in forecasting processes, in issue predictions, in scenario development or in risk management. Leveraging pattern recognition software and iterative machine learning algorithms to rapidly categorize unstructured spend, cost, contract and supplier data (e.g., information like raw AP records or T&E systems extracts not within the traditional structure of an ERP system) can deliver new insights and opportunities.

How Procurement Can Get Started on the Digital Journey?

With so many digital procurement solutions coming online, many procurement leaders struggle to determine their strategy in light of other legacy investments.

This can be simplified , if we understand the current adoption of digital procurement within the organization

Laggards :-

Organizations with minimal investments in core technologies can find value in maturing solutions that eliminate the need to make certain core technology investments (the leapfrog approach).

Recommended Processes for Digitization :-

Sourcing

SRM

Contracts management

Spend Analysis

Early Adopters :-

Organizations with a moderate level of existing investments often can use targeted investments to plug gaps.

Recommended Processes for Digitization-

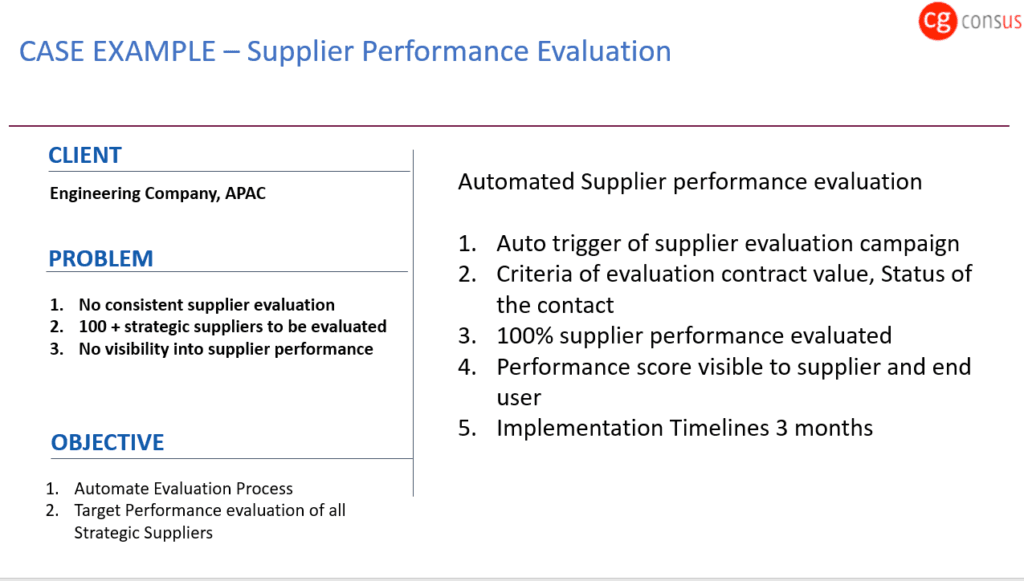

Automated Supplier performance Evaluation

Catalog Procurement

PR- PO automation

Post Order collaboration

Leaders :-

Those organizations that have made substantial investments in core technologies can utilize emerging and maturing technologies to accelerate the capture of value and help differentiate their teams.

Recommended Processes for Digitization-

Supplier Risk Analysis

AP Automation

OCR

Advance Spend Analytics

Approximate timeline for implementation of digital solutions

Digitalization Initiatives – Case Study

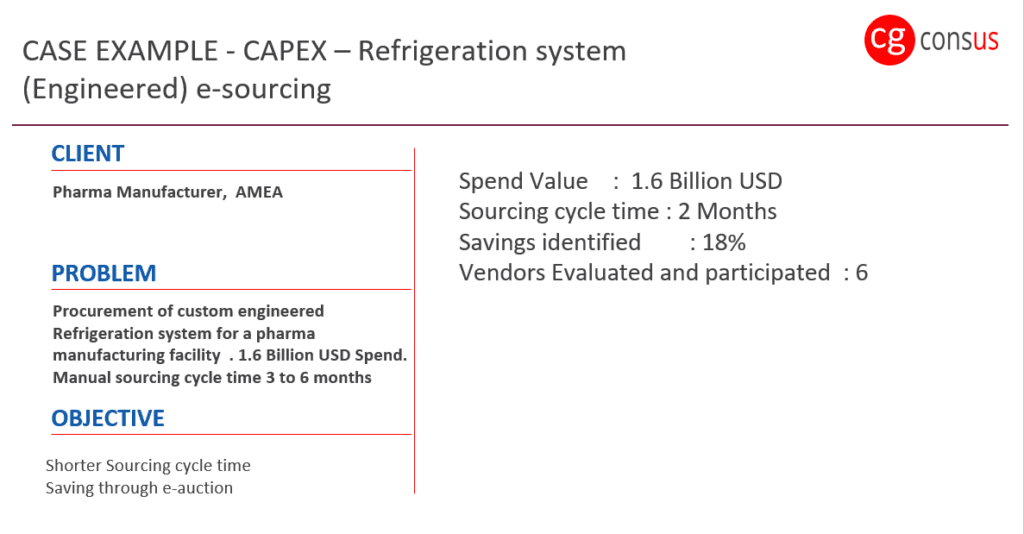

E-sourcing

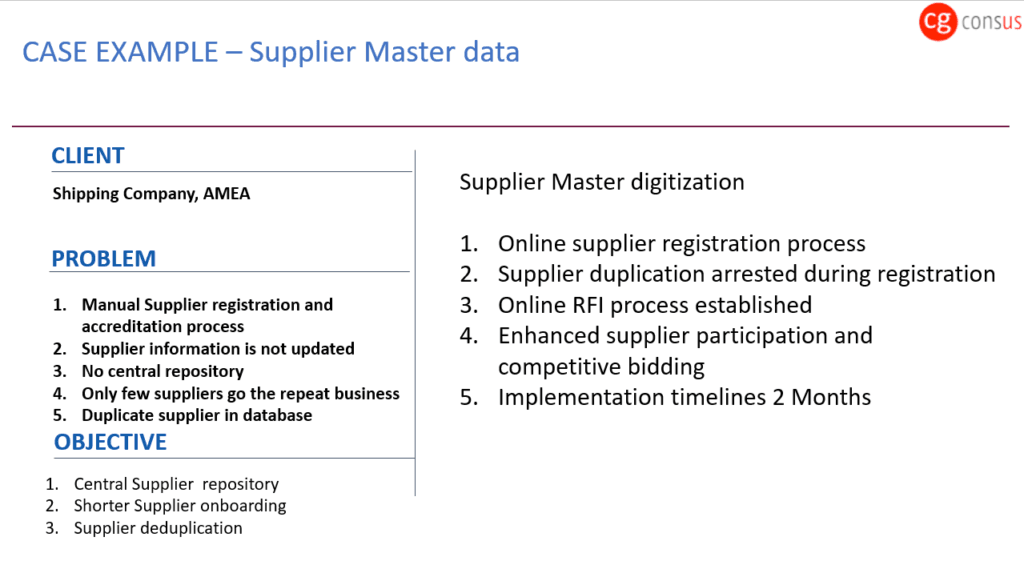

Supplier Information Management

Supplier Information Management

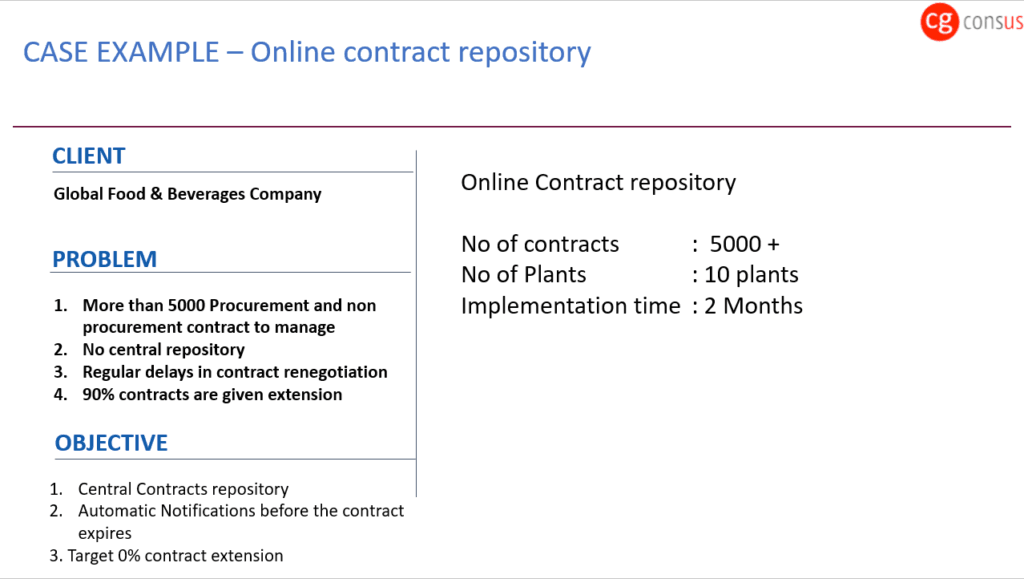

Contract Repository

RPA – Case Study

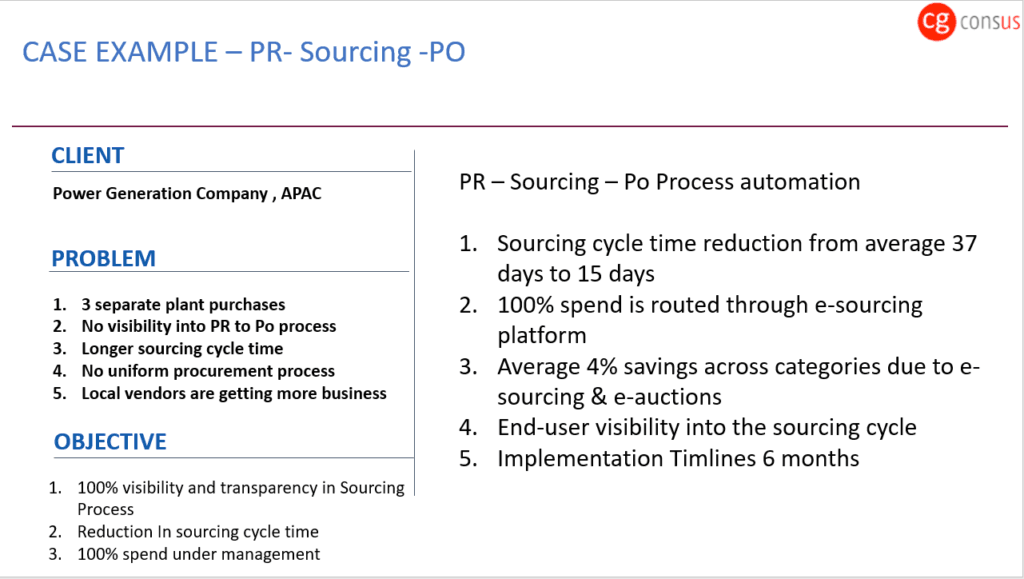

PR – PO Automation

Automated Supplier Performance Evaluation

BIG Data / AI – Case Study

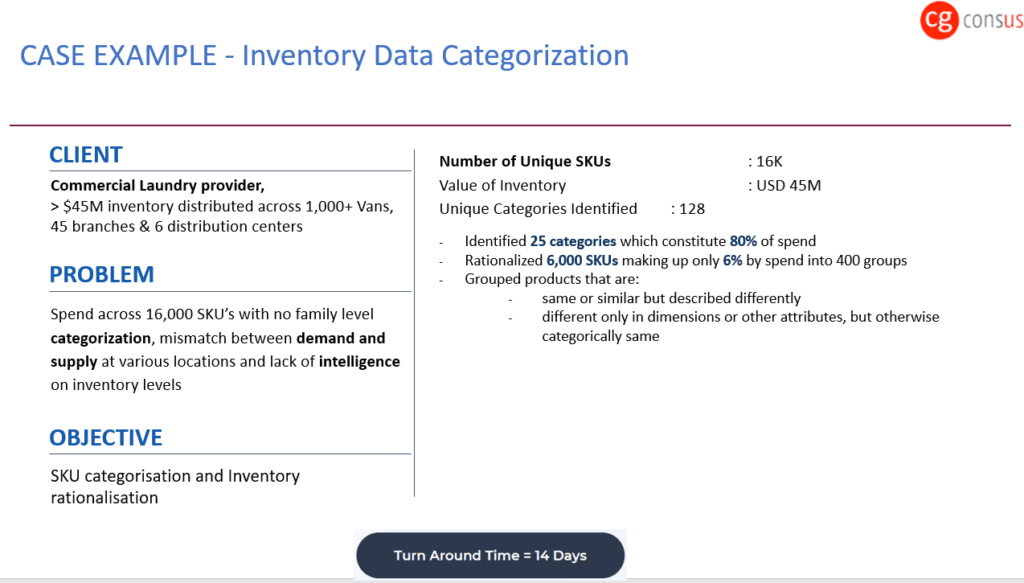

Inventory data rationalization

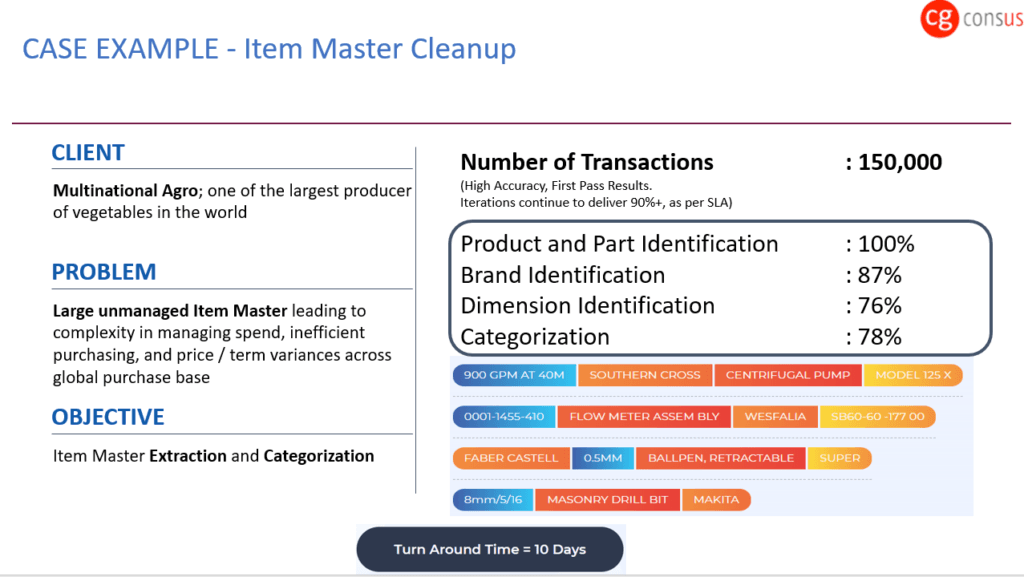

Item Master Cleanup

Our Offices

Canada

Suite 900, 1959 Upper Water Street, Halifax, NS, B3J 3N2, Canada

USA

250 Park Avenue, 7th Floor, New York, NY-10177 US

UAE

Level 3, The Offices 3, One Central, World Trade Center, P.O.Box 9573 Dubai, UAE

India (New Delhi 1)

Innov8 Coworking, Pride Plaza Hotel, H43F+ 65, Aerocity, Delhi, New Delhi - 110037

India (Bengaluru)

WeWork, Princeville Block, Embassy Golf Links Business Park, Domlur, Bengaluru - 560071

India (New Delhi 2)

S3-E, 3/F, Hansalaya Building 15 Barakhamba, New Delhi 110001, India

India (Mumbai)

WeWork, Enam Sambhav, BKC C-20, G Block, Bandra-Kurla Complex, Mumbai - 400051

Malaysia

The Horizon, Avenue 3, Tower 3, Unit 1-1, Bangsar South, Kuala Lumpur 59200, Malaysia

Singapore

20 Collyer Quay #12-06 20 Collyer Quay Singapore (049319)

Philippines

20/F, Zuellig Building, Makati Ave, Corner Paseo De Roxas, Philippines

Manila

28/F, Tower 2, The Enterprise Center, 6766 Ayala Avenue corner Paseo de Roxas, Makati City, Metro Manila 1200